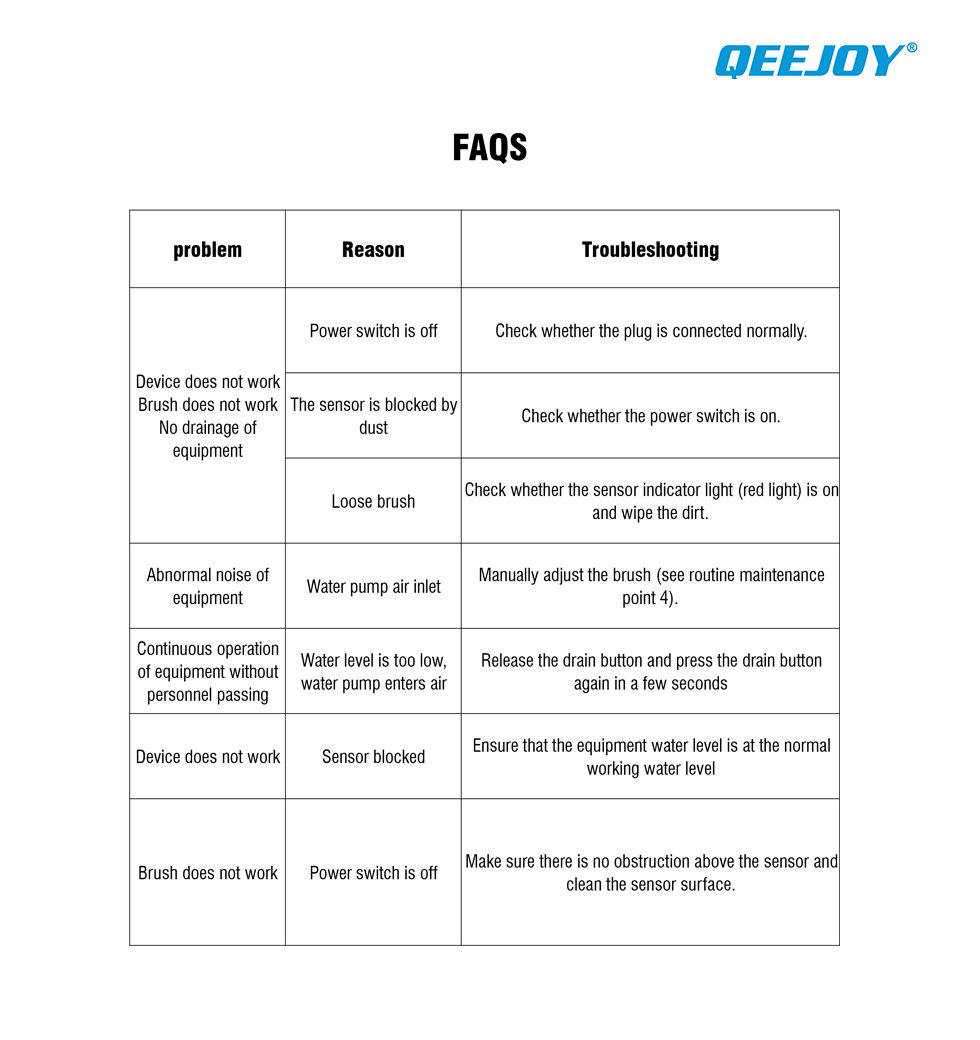

Automatic shoe sole cleaning machine E13

Control system

1. Integrated control circuit. DC24V low voltage power is used in the control circuit, which is safe and stable.

2. Point-type drainage button. Press drainage button device to drain water, release drainage button to stop drainage.

Independent cleaning module

1. lifting cleaning module. Independent cleaning zone lifts the structure to ensure that there is no cleaning dead angle and impurity residue in the tank.

2. Self-cleaning belt. The special brush press down mechanism cleans the bottom of the water storage tank by itself.

3. Separate bearing. Special shaft drive structure, spindle drive bearing and water are separate to ensure the service life of bearings and stable operation.

4. Maintenance and shutdown protection. When the cleaning module is lifted, the brush motor of the equipment cleaning will stop automatically to ensure safe use.

Efficient Dust Removal Structure

1. Inclined flume. The bottom of the tank inclines to dry zone to effectively empty the cleaning zone water.

2. Funnel-type catchment tank. A funnel-type catchment tank is arranged below the drying area to centrally empty the sewage and remove large-scale debris.

Dry zone

1. Anti-skid water extrusion board. Wave multi-orifice plate, when each time the sponge is stepped on, it squeezes the sponge; Wave-shaped structure to prevent skid and water from being sucked back by the sponge.

2. Unilateral buckle fixed sponge frame. Multi-folded sponge frame fixed with buckle and stripping and multi-folded orifice plate further increases the anti-skid property of sponge.